Pre-Production Prototyping in Dallas–Fort Worth

Engineering-Driven Prototypes That Reduce Risk Before Manufacturing

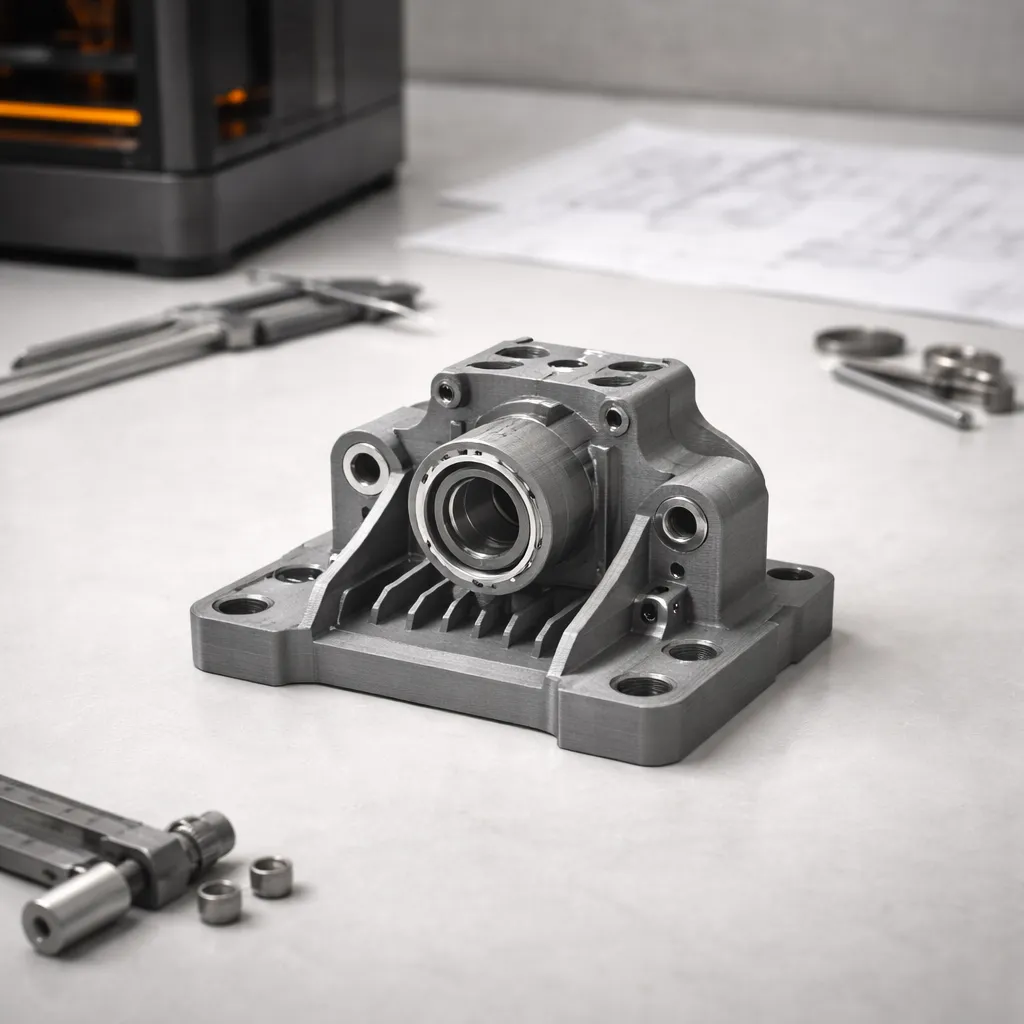

Before tooling, molds, or large production runs, companies need confidence that a design will perform as intended. Just In Time Fabrication helps product teams across the Dallas–Fort Worth area validate form, fit, and function through precision prototypes built for real-world testing—not just visual models.

What Problems Does Pre-Production Prototyping Solve?

Reveals design flaws before manufacturing

Validates form, fit, and function early

Reduces redesigns and development delays

Confirms materials and real-world usability

Minimizes risk before tooling or production

Pre-production prototyping uses functional, often 3D-printed prototypes to validate form, fit, and performance before manufacturing.

What Is Pre-Production Prototyping?

Pre-production prototyping is the process of using functional prototypes, often 3D printed to validate form, fit, and performance before committing to manufacturing. It helps engineering and product teams reduce risk, refine designs, and avoid costly mistakes during production.

This stage allows teams to:

Verify part fit and assembly

Test real-world performance and durability

Identify design flaws before tooling

Iterate quickly without committing to high production costs

Prepare designs for manufacturing readiness

Mistakes caught here save time, money, and rework later.

We frequently support clients across Dallas, Fort Worth, Frisco, McKinney, Prosper, Plano, and North Texas who need dependable prototype partners, not commodity print shops.

How Our Process Supports Better Outcomes

Review designs for manufacturability and real-world use

We evaluate designs with manufacturability, tolerances, and real-world use in mind—leveraging decades of engineering experience.

Produce functional 3D-printed prototypes for testing

Prototypes are built to test performance, fit, and interaction, not just appearance.

Iterate designs quickly based on feedback

Designs are adjusted quickly based on testing feedback, reducing risk before production commitments.

Prepare designs for manufacturing readiness

We help prepare designs for the next stage—whether that’s CNC machining, molding, or scaled production.

Why Companies Choose Just In Time Fabrication?

Engineering-First Approach – Not just printing files, but thinking through design intent

Experience That Matters – Over 30 years designing and supporting successful products

Built for Real Testing – Prototypes that reflect actual use conditions

DFW-Based, National Reach – Local collaboration with nationwide support

Pre-production prototyping is where companies are willing to invest because mistakes are expensive later. That’s why it’s the highest-value work—and exactly where experience matters most.

Frequently Asked Questions About Pre-Production Prototyping

What is pre-production prototyping?

Pre-production prototyping is the process of creating functional prototypes—often using 3D printing—to validate form, fit, and performance before manufacturing. It allows product teams to identify design issues early and refine parts before committing to tooling or large production runs.

When should a company use pre-production prototyping?

Companies should use pre-production prototyping after initial design but before investing in molds, tooling, or full-scale manufacturing. This stage helps confirm that a design works as intended under real-world conditions and reduces the risk of costly changes later.

How does 3D printing support pre-production prototyping?

3D printing enables fast, cost-effective creation of functional prototypes that can be tested, modified, and reprinted quickly. This rapid iteration allows engineers to evaluate multiple design versions without the expense or lead time of traditional manufacturing methods.

What types of businesses benefit from pre-production prototyping?

Pre-production prototyping is commonly used by product engineers, manufacturers, hardware startups, and product development teams. It is especially valuable for companies preparing for manufacturing or validating designs before production scaling.

Is pre-production prototyping only for large manufacturers?

No. Pre-production prototyping is used by both large manufacturers and smaller product teams. Startups and growing companies often rely on this process to refine designs, control costs, and move toward manufacturing with greater confidence.

Do you provide pre-production prototyping services in Dallas–Fort Worth?

Yes. We provide pre-production prototyping services throughout Dallas–Fort Worth and North Texas, supporting local and national product teams with functional 3D-printed prototypes designed for real-world testing.

Get Started With Pre-Production Prototyping

If you’re preparing for manufacturing and need confidence before committing to production, we’re ready to help.

We support pre-production prototyping projects across Dallas–Fort Worth and North Texas, working with both local and national product teams.

COMPANY

CUSTOMER CARE

LEGAL

© Copyright 2026. Just In Time Fabrication. All Rights Reserved.